IChemE helps advance catalysts for sustainable processes

25th July 2025

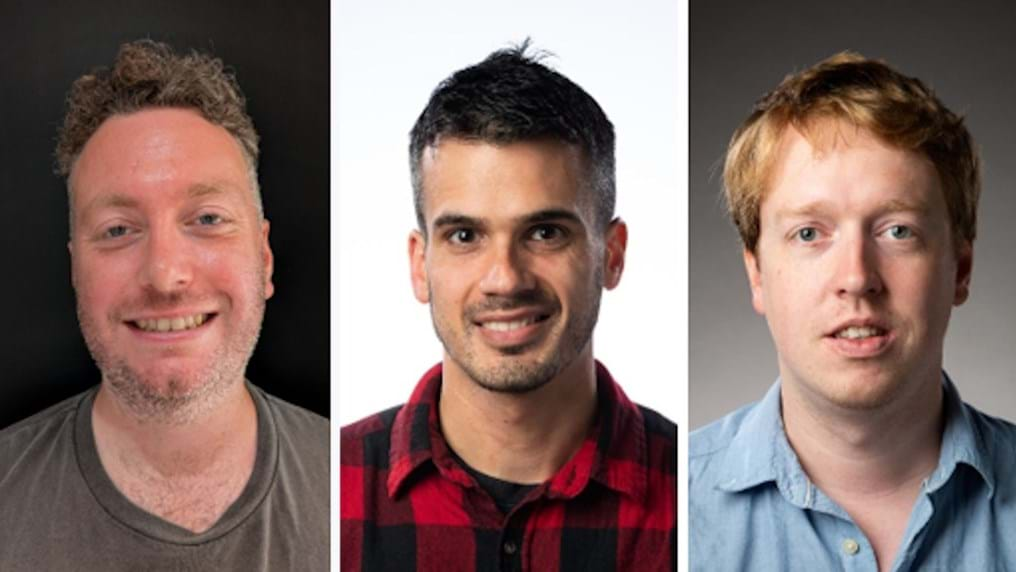

Three researchers, Alexander O’Malley, Jack Williams and Simon Freakley, have completed their Andrew Fellowships, funded by IChemE. Their work successfully investigated the detailed workings of catalysts and molecules, fluids or nanoparticles within them, to enable efficient and sustainable production of fuels and chemicals.

What is the Andrew Fellowship?

The Andrew Fellowship of the Institution of Chemical Engineers commemorates the late IChemE Fellow Professor Syd Andrew, a distinguished catalysis expert.

From 2021 to 2025, three Andrew Fellows received stipends and research expenses to advance the field of catalysis. Each Fellow was guided by a mentor – an IChemE member with experience in the field – to foster industry-academia relationships and innovation. The Fellowship enabled the three Fellows to significantly advance understanding and insight into sustainable catalytic chemical processes.

Dr Alexander O’Malley, Lecturer, Department of Chemistry, University of Bath, UK - Dr O’Malley carried out research to enhance insight into molecular behaviour in catalysts for converting bio-based feedstocks to sustainable fuels and chemicals. His work probed the relationship between catalyst pore size and composition on the mobility, adsorption and reaction behaviour of lignin-derived molecules. He applied complementary advanced experimental techniques and state-of-the-art computational methods to gain insight into, and help resolve, factors affecting mobility, which hinder the catalyst activity and lifetime, in processes for converting the large, functionalised molecules present in lignin pyrolysis oil.

The behaviour of molecules, both in the liquid state and when confined in the catalyst pores, was predicted using theoretical modelling techniques – molecular dynamics and quantum mechanical methods. Molecular and nanoscale experimental measurements, based on quasielastic neutron scattering (QENS) and vibrational spectroscopy, enabled validation of models, allowing characterisation of the types and rates of molecular diffusion present. The research furthers theoretical approaches for correlating catalyst performance and molecular behaviour.

By engaging with industry (Johnson Matthey and Zeopore Technologies), Dr O’Malley integrated crucial practical perspectives into evaluation and optimisation of promising catalysts for producing valuable chemicals more sustainably. Work enabled by the Fellowship has been published in a range of respected, peer-reviewed journals.

Access Alexander O’Malley’s full research report.

Dr Jack H. Williams, Department of Chemical Engineering and Biotechnology, University of Cambridge, UK - Dr Williams enhanced and applied magnetic resonance techniques to deepen understanding of catalytic and electrocatalytic systems. The techniques have broad applicability to catalytic reaction systems with multiple phases and spatial restrictions.

The research fine-tuned magnetic resonance techniques to a bespoke operational electrolysis half-cell, in collaboration with Shell Energy Transition Campus Amsterdam and redox.me. For the first time, magnetic resonance directly measured non-uniformity of physical and chemical properties within the electrocatalyst.

Dr Williams also applied magnetic resonance techniques in the context of Fischer-Tropsch synthesis, a reaction that converts carbon monoxide and hydrogen to liquid fuels, and which is highly relevant to the energy transition. These measurements shed light on the effect of water–hydrocarbon emulsions confined within catalyst pores on catalyst performance; in particular, results reveal that pore size is a critical design parameter, affecting catalyst wetting and hence activity and selectivity of the catalyst.

Dr Williams now employs expertise developed during his Fellowship in his role as Head Engineer of Syntholene Energy, whose technology applies electrocatalysis in the production of sustainable liquid fuels.

Access Jack Williams’ full research report.

Dr Simon Freakley, Senior Lecturer, Department of Chemistry, University of Bath, UK - Dr Freakley developed catalytic materials containing nanoparticles of copper, silver or gold that harness visible light to accelerate chemical reactions. A key aim was to elucidate structure–activity relationships governing light-enhanced, thermally-driven catalytic reactions. He showed that including these nanoparticles facilitates operation at milder reaction conditions and reduces use of precious metals, with wide-ranging potential sustainability benefits.

During the Fellowship, Dr Freakley built UK-wide research networks and helped secure a Programme Grant from UK’s Engineering and Physical Sciences Research Council. He is leading the Clean Energy work package of this project, and is collaborating with members of UK Catalysis Hub and researchers from Kings College London and Imperial College. Besides attending and presenting at several national and international meetings, he helped organise the RSC meeting ‘Chemical Feedstocks for Sustainable Industry’ in December 2024 and led a Royal Society exhibit in July 2025.

The fellowship was invaluable for advancing Dr Freakley’s scientific and experimental expertise – extending experimental methods and understanding of light-activated catalysis – and inspired research into the photocatalytic behaviour of nanomaterials with helical or spiral structures. The Fellowship also supported his professional development, with publications in the pipeline, new collaborations, grant funding, leadership opportunities, participation at conferences and leadership of outreach initiatives.

Access Simon Freakley’s full research report.

Professor Marc-Olivier Coppens, FIChemE, Ramsay Memorial Professor of Chemical Engineering at University College London, UK and Chair of IChemE’s Andrew Panel praised the research of the three Fellows: “Catalysis has an essential role in sustainable chemical processing, which needs new technologies and new chemical pathways. These Andrew Fellowships have nurtured professional development and enabled excellent scientific progress that is practically and industrially relevant and aligned with the UN Sustainable Development Goal of Responsible Consumption and Production. The work of Alexander, Jack and Simon supported by the Andrew Fellowship is already having an impact on industrial application of catalysis, ongoing research, research leadership and outreach to the next generation of scientists and engineers.”

Professor Joan Cordiner, IChemE Vice President (Learned Society) said: “Let’s congratulate Alexander, Jack and Simon on their impactful research. Their achievements underline the importance of scientific and chemical engineering innovation for solving sustainability challenges. IChemE’s Andrew Fellowships offer talented early career researchers an excellent opportunity for technical and professional development, with mentoring that helps to propel research towards solutions that are socially, economically and environmentally sustainable.”

The Andrew Fellowship was revised and relaunched in 2024. It now covers full salary costs plus research expenses for up to two early career researchers for a 12-month period. The goal is to enable the Fellows to undertake independent, industrially relevant research in the field of heterogeneous catalysis. Applications are open until 1 December. Find out more and apply.

What is chemical engineering?

Chemical, biochemical and process engineering is the application of science, mathematics and economics in the process of turning raw materials into everyday, and more specialist, products. Professional chemical engineers design, construct and manage process operations all over the world. Energy, pharmaceuticals, food and drink, synthetic fibres and clean drinking water are just some of the industry sectors and products where chemical engineering plays a central role.

IChemE

The Institution of Chemical Engineers (IChemE) advances chemical engineering's contribution for the benefit of society. We facilitate the development of chemical engineering professionals and provide connections to a powerful network of around 32,000 members in more than 100 countries.

We support our members in applying their expertise and experience to make an influential contribution to solving major global challenges, and are the only organisation permitted to award Chartered Chemical Engineer status and Professional Process Safety Engineer registration.